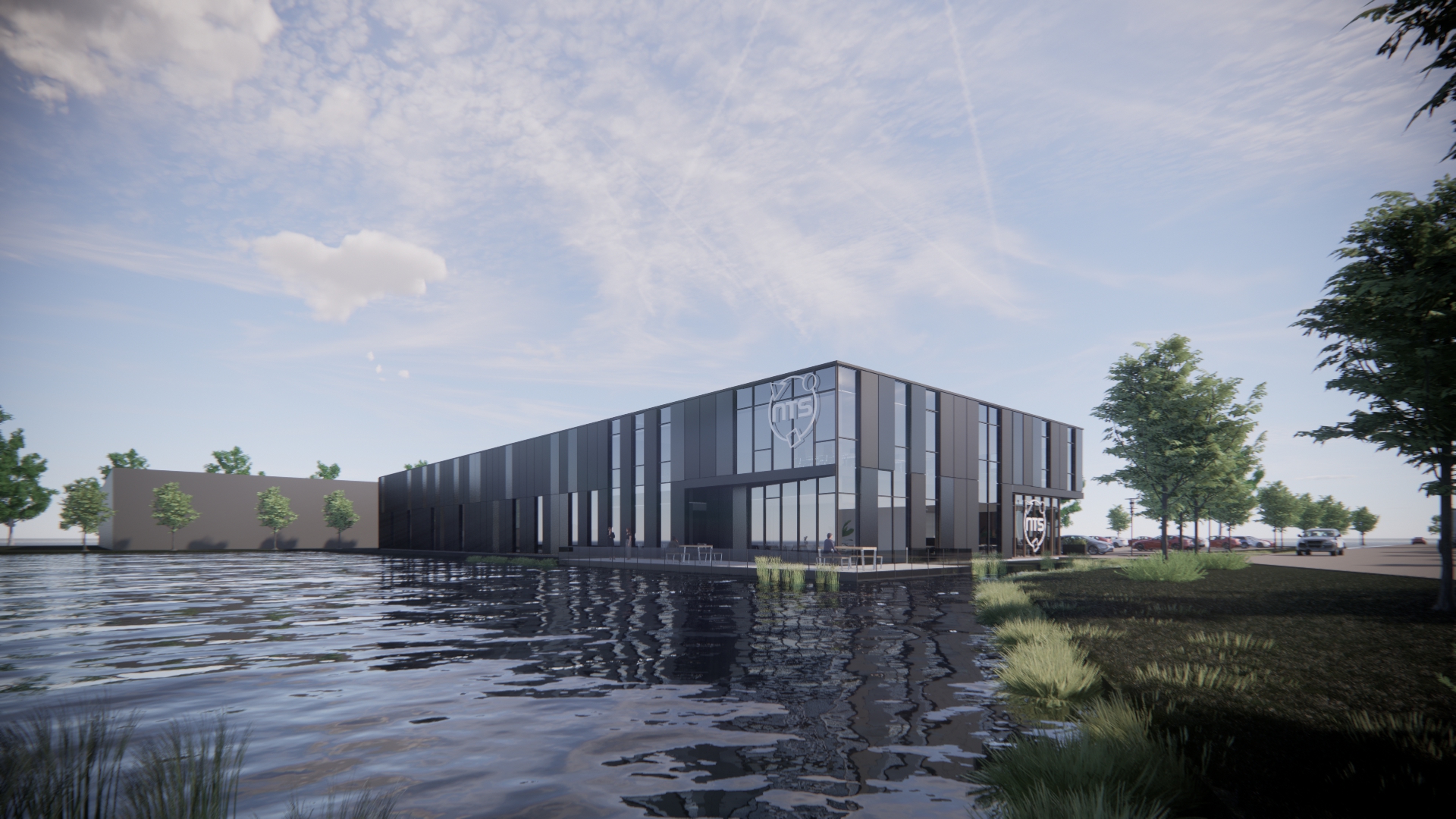

Factory of the future for NTS Drachten

NTS will be building a ‘factory of the future’ at a location visible from the A-7 in Drachten in the nearby future. NTS Norma Drachten has a unique position worldwide when it comes to precision machining and ultra-precision parts for markets such as semiconductor, medical technology, life sciences & analytical and optics. The demand for ultra-precision parts is high and is expected to increase further due to developments such as 5G and IoT. For that reason, NTS has decided to invest in a future-proof sustainable building with optimal conditions that also offers a pleasant working environment for its committed employees.

NTS invests in building with optimal conditions to produce ultra-precision parts

“Ultra-precise, ultra-small and ultra clean. That is what it is all about at NTS Norma in Drachten,” says Klaas Geschiere, Managing Director of NTS Norma in Drachten. “We make extremely complex parts from complex materials at micron level, among others for the semiconductor and life sciences & analytical industry. Our customers are located all over the world. Here we operate at the boundaries of manufacturability. When high-tech OEM customers have issues with the production of their complex parts and associated processes, they know where to find us. Due to our variety of competences under one roof, we are one of the few companies in the world that can guarantee an accuracy and cleanliness of (less than) one thousandth of a millimeter with various complex materials.”

New building to achieve optimal conditions

“We are quite unique in what we do. This is due to a combination of craftsmanship, years of experience, a mix of highly experienced professionals and young people with fresh ideas and the right machines. We see that the demand for ultra-precision parts has increased and we expect this to continue in the future. To be able to meet this expected demand, we need a factory with optimal conditions. Therefore, we have decided to build a new factory. We are currently renting an existing building. When it comes to optimal conditions and design, the current building does not match our future ambitions.”

Factory of the future

“When you work at a micron level, things like floor stability, optimal air quality, routing, well-designed cleaning lines and having the right machines in the right place are essential. A new building can be fully adapted to our demands. It will meet all the conditions we need to produce and all the sustainability requirements that we defined for NTS buildings and it offers us the opportunity for digitization and advanced manufacturing techniques. Material science and production science are of great importance if you must act at a crystal level. You could say that our building will be a factory of the future.”

Anticipate permanent demand and build in flexibility

“With the construction of our new building, we are anticipating on our roadmap for the future. This also means that we will not be using the entire lot immediately but also retain space to be flexible in the future. In this way we can continue to meet the growing demand for ultra-precision components. Our employees are closely involved in the development process of the new location. Someone from each department is represented in the consultative group.”

Increased demand for chips caused by various developments

“The increased demand that NTS has to deal with in Drachten is partly due to a shortage of chips,” explains CEO of NTS, Tjarko Bouman. “We have seen tremendous growth in recent years and we expect that demand will continue to grow in the future as a result of developments such as IoT, 5G and autonomous driving. A large part of our business comes from the semicon industry, but also our medical and analytical markets will keep on growing. In Drachten we were simply at the maximum of our capacity.”

Miniaturization trend leads to challenges at the boundaries of manufacturability

“In addition, the miniaturization trend and the associated complexity are important drivers for our growth,” continues Klaas. “Because components are getting smaller and more complex, what we do is increasingly at the boundaries of manufacturability, and that is why customers come to us. In addition, it is an absolute advantage for customers that NTS has many disciplines under one roof. We therefore have to outsource as little as possible."

Sustainable entrepreneurship mainly means investing in people

“As far as the new building is concerned, we are now in the design phase. We first looked at the technology, at what we need and what that means for the design. We then enter into discussions with architects, contractors and other parties. As mentioned, our employees are involved in the process. We want to create a pleasant working environment. Sustainability is not only in a building and energy use, but especially also in committed employership. We therefore invest in our people and their development. Our culture is that of a family business, people who work here have an enormous passion for their work. Our employees are a mix of well-trained craftsmen and several highly educated employees. For this we use the talent pool that is present in the region. In addition to schools for secondary vocational education and Universities of Applied Sciences, we also have contact with, among others, the University of Groningen. "

Good, experienced people are always welcome

“From a labor market perspective, there are only few companies such as NTS in the Drachten region. Many professionals who want to work at the boundaries of manufacturability in an attractive environment with the latest high-tech equipment come to us. We are also an attractive employer to people who started their career elsewhere in the country, but want to come back to live in Friesland later. Good, experienced people are always welcome.”

In case you would like to contact us, you can fill in the contact form here. We will respond to you as soon as possible.