NTS invests in additive manufacturing and installs cutting-edge 3D printer

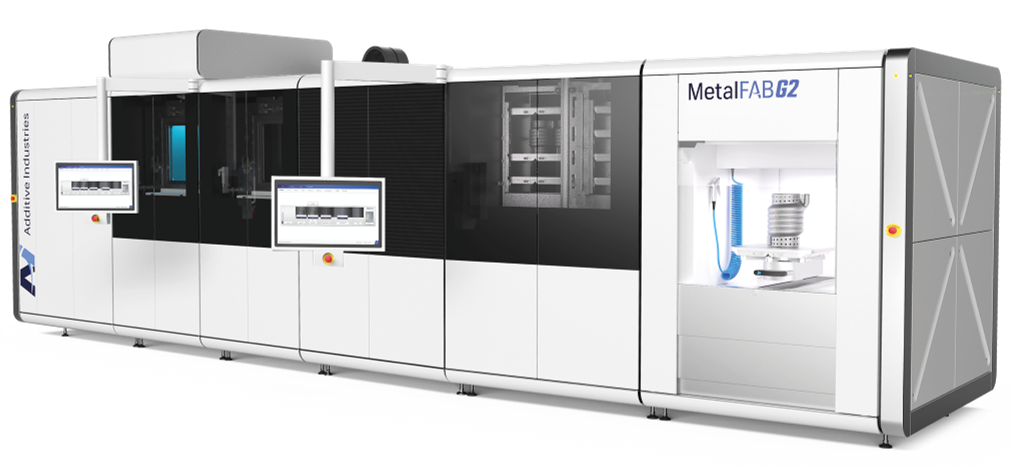

Eindhoven, Netherlands – 21 Feb. 2022 – NTS-Group, a leading high-tech systems supplier, announced today that the company has installed a cutting edge MetalFABG2 3D printer at its Hengelo location to better serve high-tech OEMs in semiconductor, analytical and health markets.

Additive manufacturing is becoming increasingly accepted as a valid production method by leading high-tech OEMs. Companies have been aware of the benefits of this technology for years. The technology has now been proven to be able to manufacture components that consistently meet the desired quality standards. In addition to the inherent advantages of this technology, the current supply chain pressure experienced by OEMs also plays a significant role; additive manufacturing lead times are significantly shorter than conventional manufacturing methods.

“Additive manufacturing capabilities are a great addition to our competences and central to our business strategy,” said Tjarko Bouman, CEO of NTS-Group. “We are constantly striving to expand our added value for high-tech OEMs by offering more cost-efficient manufacturing, a shorter time-to-market and faster prototype development. Our new industrial MetalFABG2 printer from Additive Industries is equipped with three large build chambers and four lasers, which enables high productivity and repeatable quality for our customers. We are working on a wide range of applications for key customers.”

Additive manufacturing competency

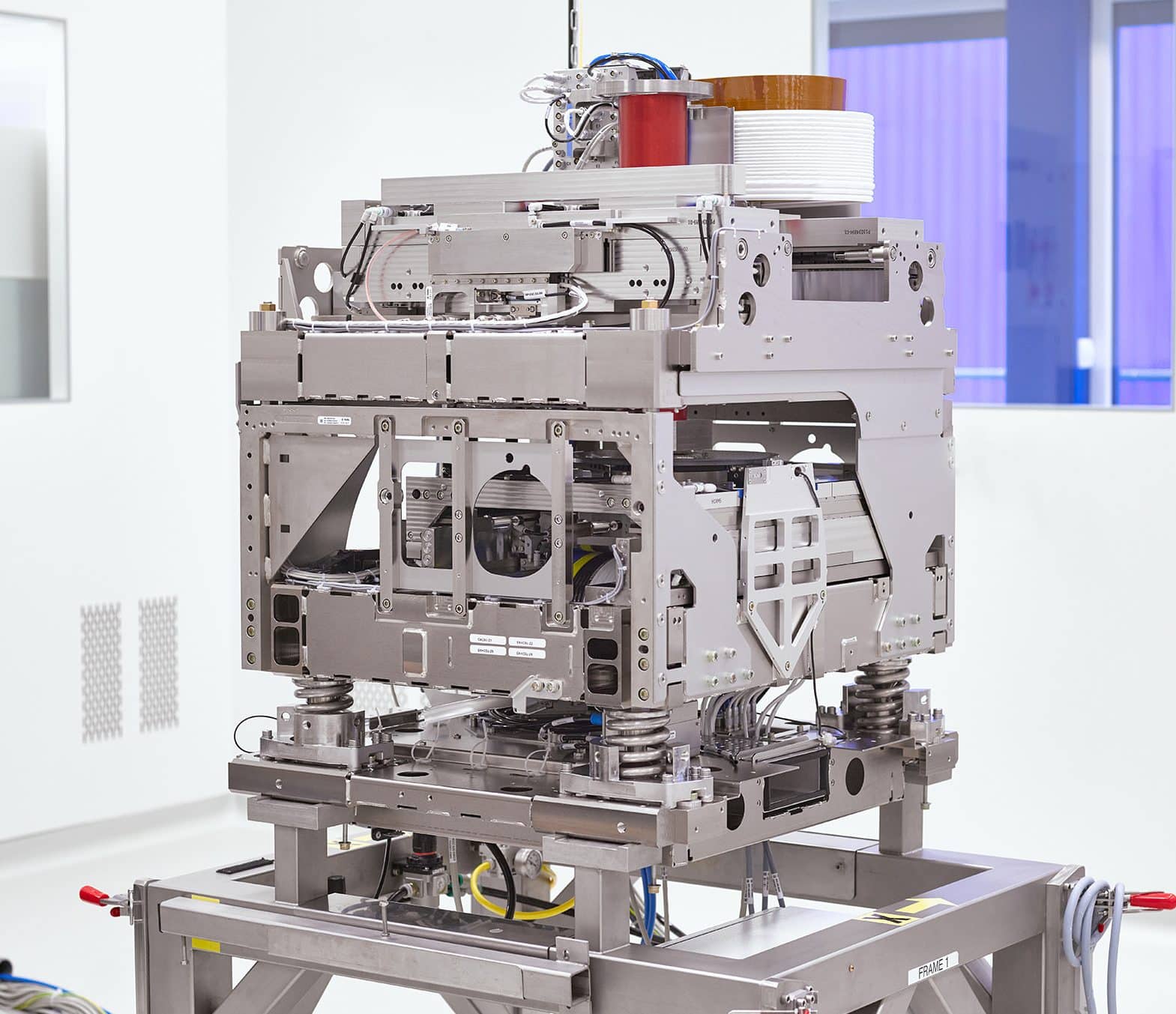

NTS has been experimenting with additive manufacturing since 2013 and has developed its competency through various collaborative efforts. NTS was one of the founders of AddLab and AddFab, a 3D printing factory with the ambition to develop world-class 3D printed metal parts for a broad range of high-tech and high-end manufacturing applications. Its Drachten location was home to the 3D printer of another consortium actively working with the technology. The expertise and experience gained through these initiatives by NTS’ 3D printing competence team was central to its decision to purchase a MetalFABG2 and offer significant manufacturing capacity, in-house, to its customers.

“Starting with the more efficient and faster production of conventional parts, we guide our customers through the world of 3D printing,” said René Vlaskamp, Fellow at NTS-Group. “Our next step will be to change the engineering mindset and redesign key parts together with additive manufacturing in mind to unlock additional value. That will allow us to manufacture consolidated parts and improve part performance significantly. Lighter parts with improved performance will, for example, allow OEMs to further improve the efficiency of their applications.” With the new 3D printer, NTS has the capability to print titanium, stainless steel, aluminium and is developing other exotic materials.

Advantages of 3D printing

NTS considers the following as the main advantages of 3D printing for high-tech OEMs:

- Part consolidation

- Decreased mass of components

- Part performance improvement

- Shorter manufacturing lead times

- Reduced inventory costs

In case you would like to contact us, you can fill in the contact form here. We will respond to you as soon as possible.