In high-tech equipment, high precision components must be able to perform both accurately and reliably. To ensure that, equipment manufacturers are increasingly forced to rely on an increasing range of materials and treatments. Lighter, stiffer materials, materials with low or high conductivity, with low or high heat conductivity, low expansion materials, anti-magnetic properties, granite, EMC or acoustic shielding etc. It is essential to have the required knowlegde on how to exploit and process these materials.

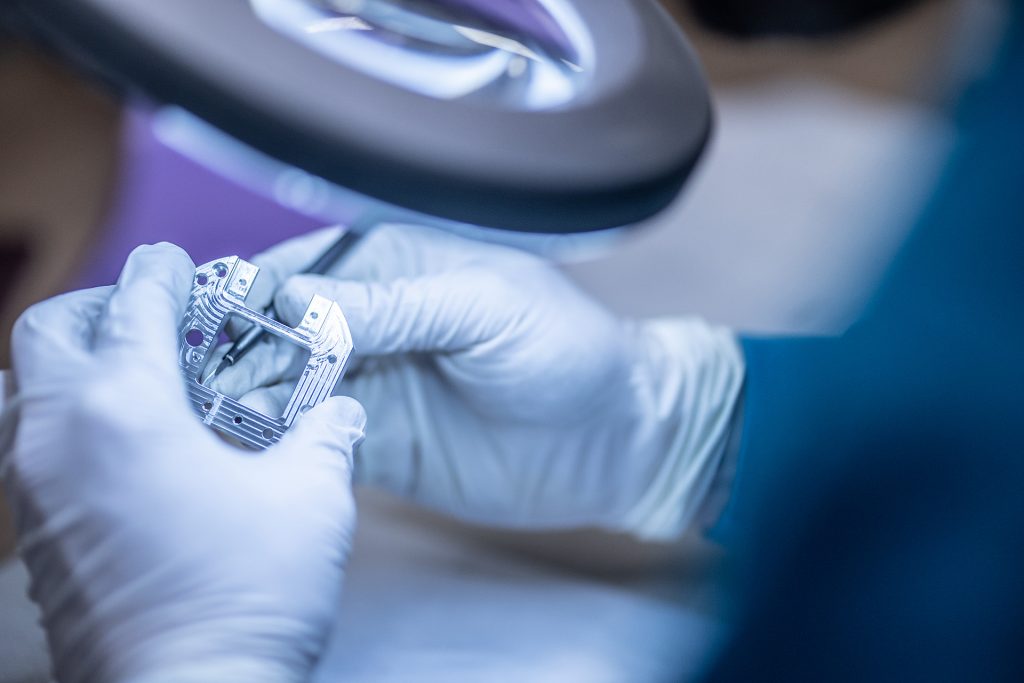

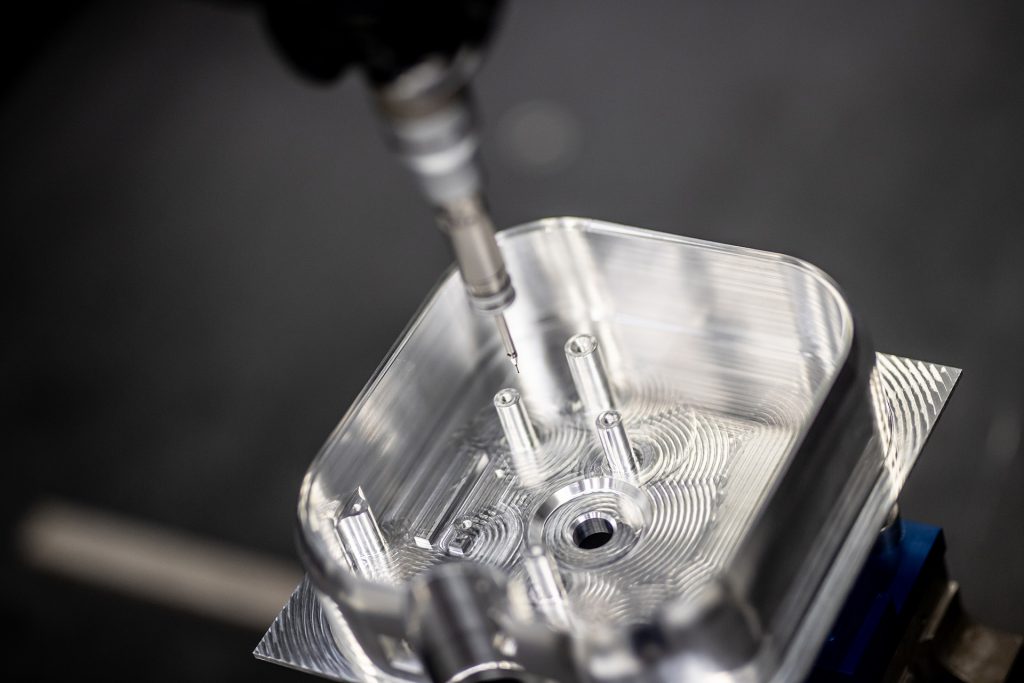

At NTS, we are used to the widest range of materials used in high-tech manufacturing. Our engineers think along with our customers to develop and manufacture products that best meet their requirements. That’s why NTS is one of the few companies in the world that can guarantee accuracy of less than one thousandth of a millimeter. But, in order to do that, besides our value engineering, we also depend on another core competence – our material and (surface) treatment expertise.

Process Knowledge and Domain Knowledge

The range of raw materials and properties is massive. But also during manufacturing, properties change and can be purposely influenced. For example with heat treatments, surface treatment or finish layers. Obviously, all these steps need to be tuned into a precision result, requiring expertise and diligence. Because of our domain knowledge we can quickly choose the right materials, treatments and special purpose finishes.

Combining Infrastructure and Expertise

At NTS, we think along with our customers to develop and manufacture products that best meet their requirements. At every step – right from development, mechanical design to material selection and then manufacturing – we keep the time-to-market and the costs, optimal. Our specially trained material technologists choose a particular material or combination of materials, based on the desired application, the desired durability or the quality requirements. We have ample expertise and experience with different types of steel (including hardened steel), aluminum, special alloys (such as nickel and titanium) as well as granite or composites. Our material technologists always make a well-founded selection in order to provide the customer with the best possible application.

Besides our technologists, we also work with state-of-the-art machinery, to produce these high precision components for our customers. Read more about our realization capabilities with respect to precision components and precision frames and cabinets.

“Our team of metallurgists is involved in projects that to determine the surface treatments necessary to meet the customer requirements in ultra-precision.”

Tom Kruse

Sales & Account Manager at NTS Drachten

One-stop-shop

NTS is uniquely positioned in its capacity to bring various capabilities and competences to collaborate, to meet your specific requirements of performance parameters and costs. Having everything in-house means the turnaround time for design cycles is faster, the process is more streamlined and there is no loss of information. Partnering with NTS enables our customers – OEMs in semiconductor and analytical industry – to achieve next levels in performance.

Download our Whitepaper about Premium Surface and Technical Coatings for high-end Applications

For years, coatings were used primarily to prevent corrosion or wear and generally improve the appeal of products and components. Selecting the appropriate coating was a step often taken at the very end of the development process and was usually a straightforward choice: what is the material of my substrate and what look and feel do I want? But the increased application of plastics in a wide variety of markets, and technical requirements becoming more challenging, we have seen demand for so-called technical coatings grow significantly. Such coatings can add specific characteristics to products and/or allow for significant product innovation.