Creating custom optical and laser solutions, for high-complexity and high-mix markets is not easy. It requires a fusion of multiple specialized skills and knowledge. International OEMs -that want to design, develop and manufacture these high-precision, measurement and testing solutions at speed – face a daunting challenge. The solution? NTS’ unique combination of optics, software, electronics and mechanical expertise and experience.

With NTS, our customers have a partner that can develop, assemble and test complex optical, laser and opto-mechatronic tooling, systems and modules, both for one-off and repeat production. And do that with time efficiency. In other words – we support our customers in staying ahead of the competition, both in terms of time-to-market and technological development.

Application Areas

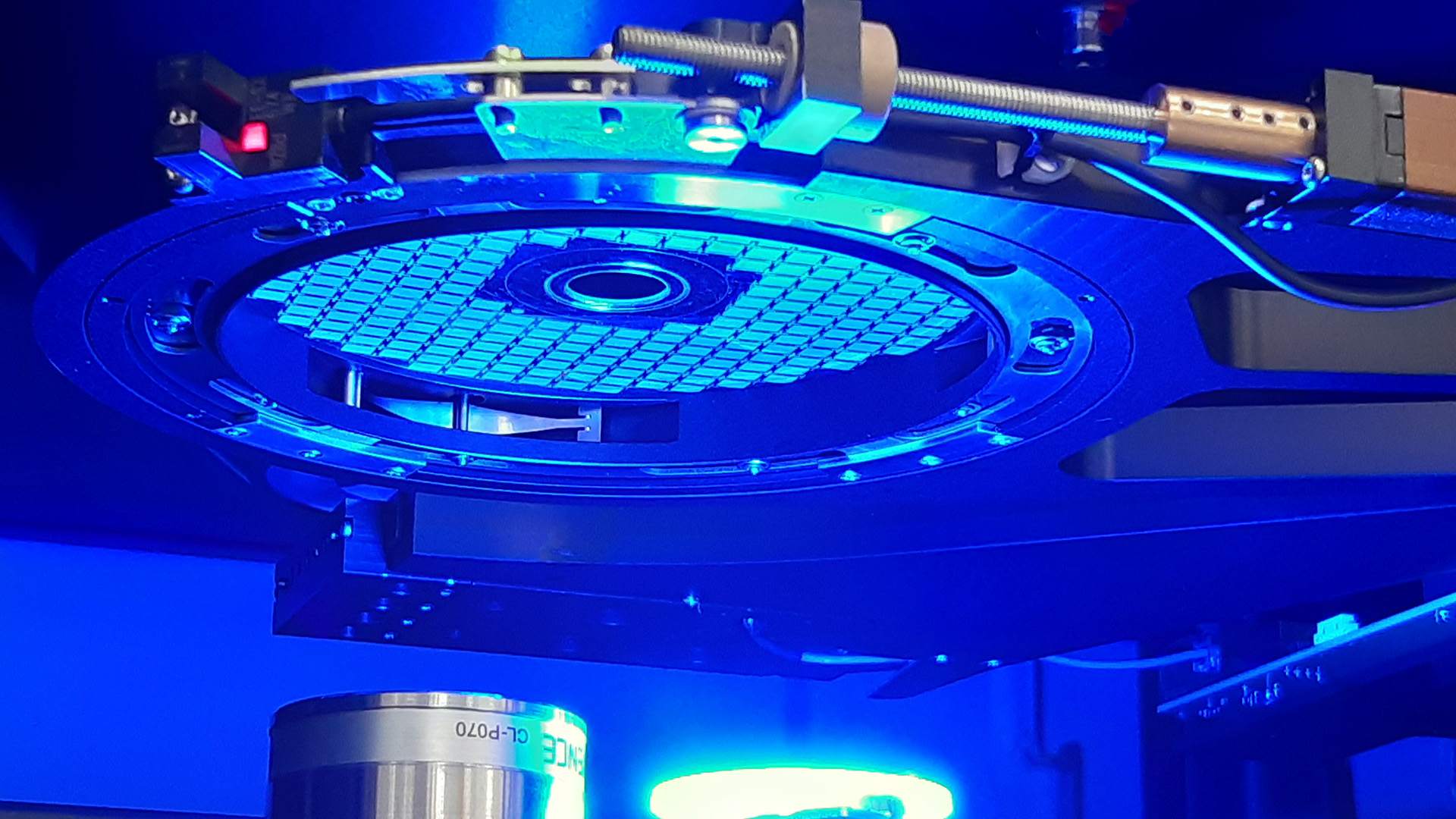

What is common between electron microscopes and silicon wafer manufacturing? The ability to attain precision, aided by our optical and laser solutions. From ocular surgical instruments, level sensors in semiconductor equipment, to tooling for optimal levelling of silicon wafers and sensors to determine the firmness of cheese curd: we bring in our engineering expertise and fit-for-purpose processes to produce optimal solutions for our customers. Our applications include illumination, imaging and sensing solutions, laser beam delivery as well as integrated Nanostructure testing solutions. We have developed over 100 custom test & measuring solutions and opto-mechatronic systems in our core markets.

Idea to Working Prototype: Faster Time-to-market

How do we corporate with OEMs? We can take their challenge or idea, add our engineering and multidisciplinary expertise to get a best-fit design and build a working prototype quicker. Having all the capabilities in-house, including optical lab infrastructure, means faster time-to-market and continuous on time delivery for our customers. Once the prototype is final, we can move to small or large series inhouse production.

NTS houses both development and production capabilities together, resulting in logistics and communication efficiency and shorter turnaround time, as well as the same high quality, every time. Regardless of whether a customer outsources manufacturing or does it in-house, we ensure that the delivery timelines are seamlessly aligned with their supply chain.

“Move seamlessly and quickly from Initial Thought to High Quality Custom Optics and Laser Solution in the Fields of Illumination, Imaging, Beam Delivery, Sensing Applications and integrated Nanostructure testing solutions”

Leon Hol

Managing Director at NTS Nijmegen

Added Value as a Partner

At NTS, our combined proficiencies in optics, electronics, software and mechanics are constantly pushing the boundary of what is possible, allowing applications in ever smaller dimensions, enabling increased usability and lower cost. Which we can then pass on to our customers. We believe in lasting partnerships and are growing with our customers. We share our successes, lessons learned and improve continuously. And we always deliver. Which is why, our customers find value in NTS as an experienced partner in development, manufacturing and life cycle management of their products and modules.

Download our Whitepaper about the Navigation Camera for Electron Microscopes

In this whitepaper, you will find the following topics:

- Technological insights in the design, development and production of the Navcam.

- The technological challenges which had to be faced and how they have been resolved in order to create the optimal solution for our customer.

- A case description of the custom built-in navigation camera.