NTS Drachten is the partner of choice when it comes to ultra-precise manufacturing up to 1μm accuracy and complex mechatronic assemblies, all under one roof. At our sites in Drachten and Hengelo (the Netherlands), we also support our customers in the semiconductor and analytical industry with their design of mechatronic systems.

Our customers have highly intricate requirements in terms of dimension, complexity, and cleanliness. In recent years, we have focused on developing all the necessary in-house competencies and facilities to meet and realize the needs in these markets. Our employees possess the skills and undergo all necessary training, to ensure they succeed and enjoy their everyday challenge, of making the impossible possible.

Engineering

For our customers time-to-market is of the essence. To prioritize that, we support them from an early design phase. With an on-site embedded design and engineering team, we are able to meet all their requirements with relation to:

- Early supplier involvement and build to print +

- DfX – improve manufacturability along with the customer, with knowledge of function and application

- Value Engineering – run cost improvement programs

- Co-engineering – support customers so they can focus on their functional design

Manufacturing & Assembly

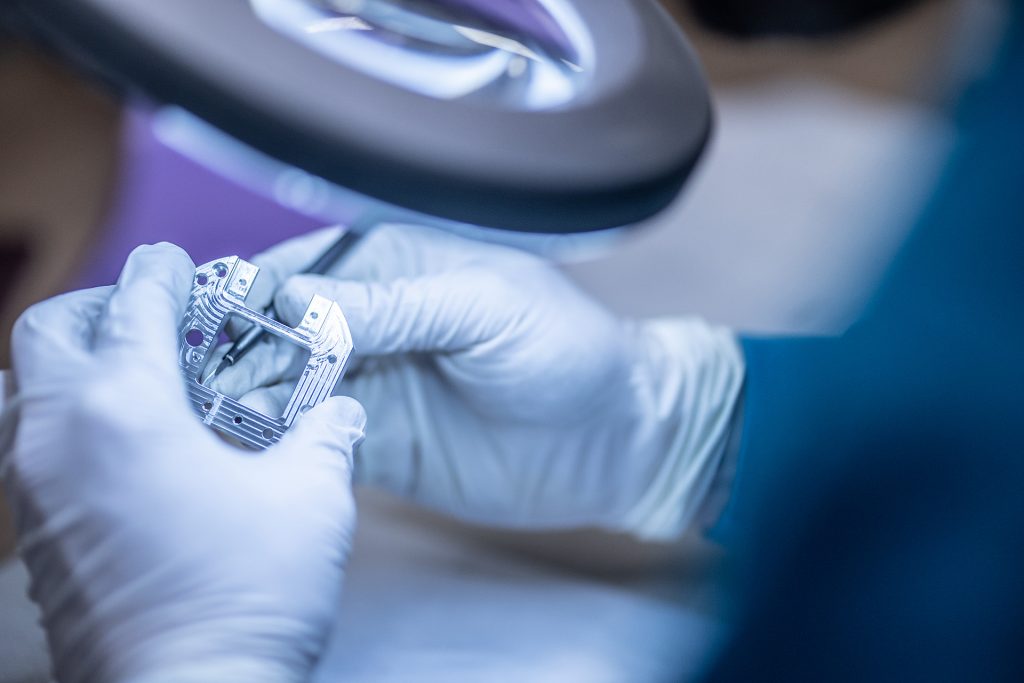

The core activity of NTS Drachten is (ultra) precision manufacturing. For this we have a broad range of in-house machining along with other capabilities, which we believe are a prerequisite to be successful: namely in-house heat treatment, competence teams for heat treatment, material science and cleanliness. Though both the ultra precision sites have the same competences, the Drachten facility focuses on the smaller and smallest components.

At the Hengelo location, we also specialize in cleanroom assembly, qualifying and testing. Here, the focus is on mechatronic assemblies, where the functioning relies on ultra-precision parts. With our cleanroom close to the component manufacturing facilities, preventive troubleshooting is easy. Another area of our expertise, is in vacuum brazing, a high quality brazing solution for achieving high quality joints.

Managing and Qualifying the Supply Chain

NTS is a first-tier contract manufacturer for ultra-precise, complex parts and mechatronic assemblies. In this role we unburden our customers, by setting up, qualifying and managing the entire supply chain, so they can focus on their core functionality instead. That success starts with our people. Our colleagues, from varied disciplines, work together in close-knit teams. We put a lot of effort in education, partially by ourselves, to be able to meet the highest standards and requirements. Additionally, over the past 65 years we have built an impressive state-of-the-art machine park, where we offer a broad range of competencies and guarantee the highest quality. All our core competences needed for building ultra-precise parts result in an impressive track record.

Download our Whitepaper ‘Ultra-precision Parts for E-Beam Inspection’

In today’s market, more and more small precision components are needed. The future therefore lies in making sub-nano components. Making ultra-precision components is our core competence, with specialized locations in Drachten and Hengelo. In this whitepaper, our experts discuss:

- Ultra-precision component manufacturing;

- Ultra-precision in e-beam inspection applications;

- A project for one of our semiconductor customers.

NTS Whitepaper Ultra-precision components – Customer case

NTS Drachten in Numbers

0

0

0

0

Ultra-Precision Components

While components are getting smaller, we are getting more precise. NTS is one of the few in the world that can manufacture parts under an accuracy of (less than) one-thousandth of a millimeter. Having all expertise in-house makes us a one-stop-shop for precision components.

Read more

Cleanliness & Vacuum

Cleanliness is a core competence at NTS. It is embedded in all layers of the organization . Every step of our development and manufacturing processes are designed with cleanliness optimization in mind. We invest heavily in equipment as well as knowledge-led expertise in contamination control and vacuum technology, to meet the strictest challenges

Read more

Materials & (Surface) Treatment

Proper material selection and surface treatment is the backbone of precision component manufacturing. As these are used in high-tech equipment and modules, using the right material technology and treatment ensures that these components perform accurately and reliably, with high accuracy. At NTS we rely on our domain expertise and excellent machining infrastructure to meet these needs.

Read more

E- & Ion-beam

While components are getting smaller, we are getting more precise. NTS is one of the few in the world that can manufacture parts under an accuracy of (less than) one-thousandth of a millimeter. Having all expertise in-house makes us a one-stop-shop for precision components.

Read moreContact

Want to know more?

In case you would like to contact us, you can fill in the contact form here. We will respond to you as soon as possible.Locations

Drachten

Scholtenlaan 1

9207 JW Drachten

Nederland

+31 (0)88 66 76 801