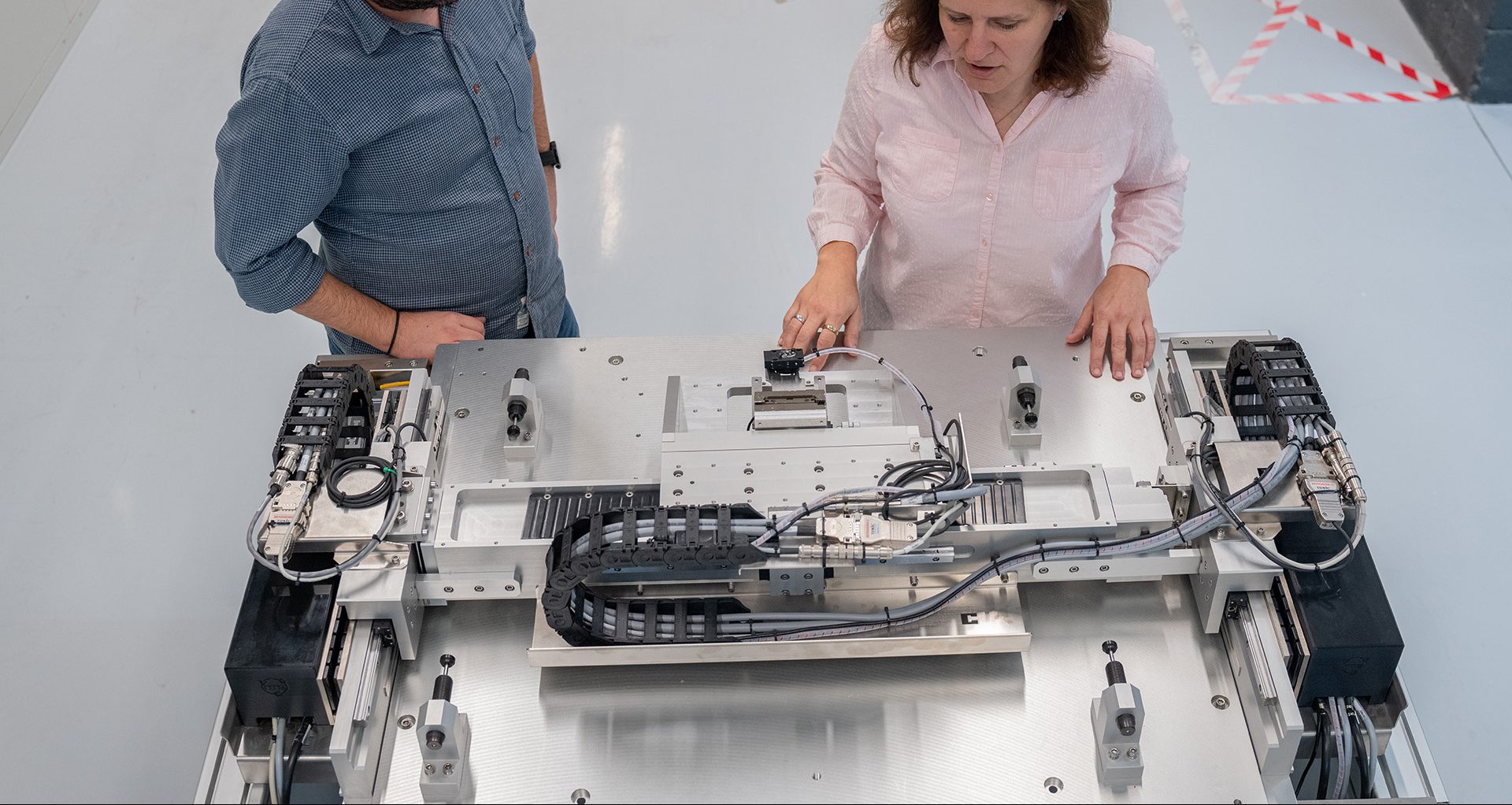

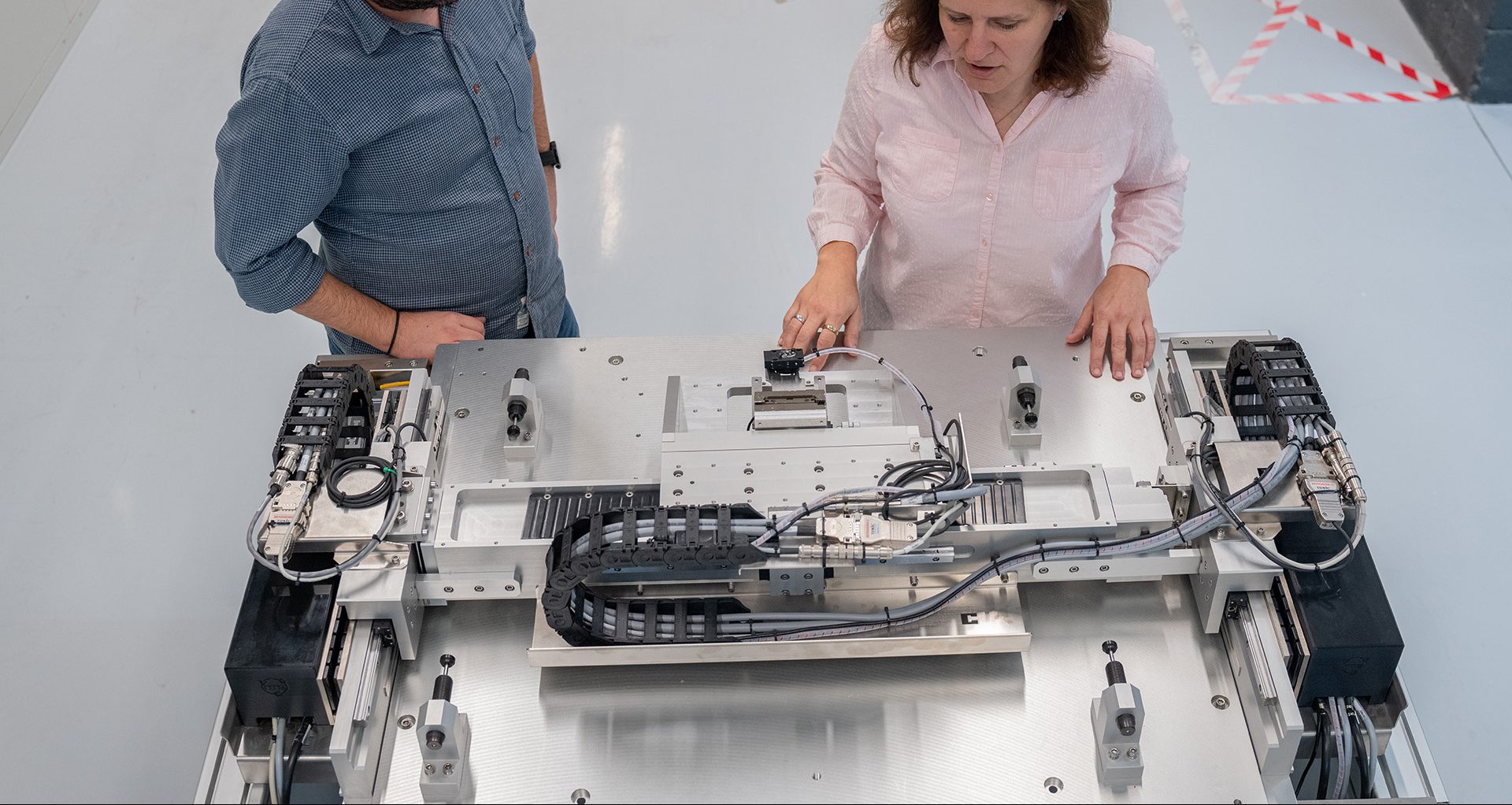

Today’s advanced high-tech factories and manufacturing facilities require faster, more accurate and smarter systems. Because of increasing complexity, OEMs in the semiconductor and analytical industries, rely on their suppliers to build high-tech systems. Therefore, working together with (co-)development and manufacturing partners is smart. Especially when time-to-market is key.

At NTS, we are equipped to develop, design, and industrialize series of high performing and ultra-accurate systems. From starting with a set of functional requirements to arriving at the factory floor: mechatronics is the key competence you need in the next generation of high-tech systems.

Mechatronics: Building the Next Generation of Better and Smarter Systems

Mechatronics as a multidisciplinary field of expertise is essential for developing and building the next generation of high-tech systems. It combines mechanical, electronical and software skillsets, together with in-depth knowledge about machine dynamics. Concretely, this means knowing how to make precision structures, how to select, and simulate the type of motors that are needed, how to choose the right position-sensors to measure accurately, how to design the electrical cabling and how to select the best precision motion control platforms. At NTS, we define mechatronics with the following competencies:

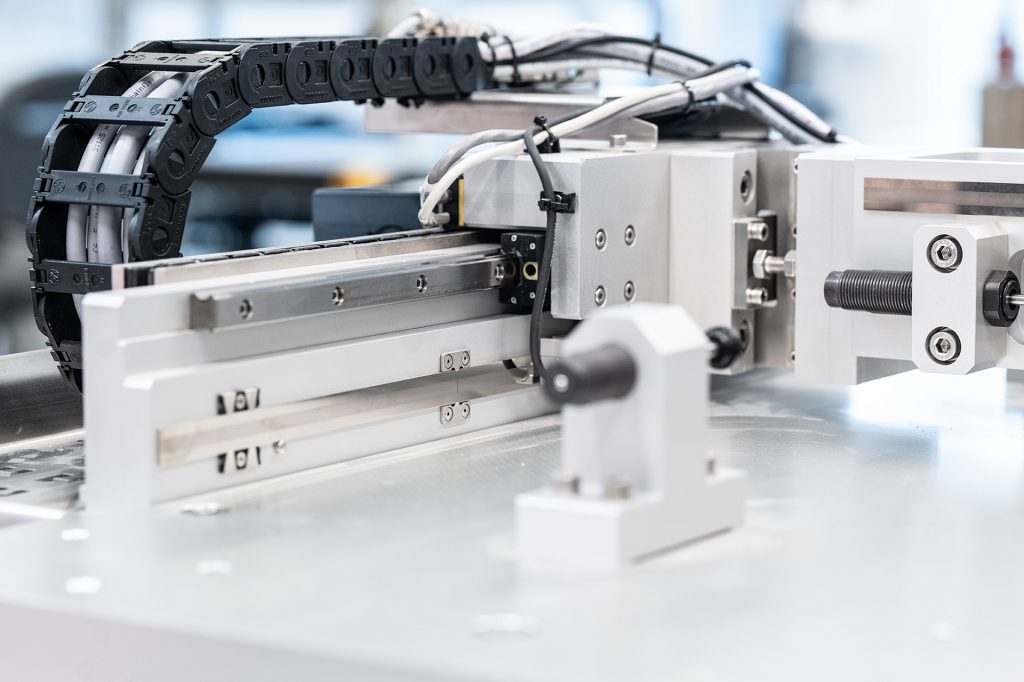

- Design of precision mechanics. We understand that a good mechanical design serves as the basis of a fast and accurate piece of mechatronic equipment. Design for stiffness and design for high natural frequencies are the starting point to maximize performance.

- Motion control for ultra-precise positioning. At NTS, we have the classic motion control skills such as design of PID-controllers as well as deep knowledge about more complex motion control architectures. Key in effective machine development is the knowledge of how to implement this in industrial motion controllers and maximize performance with available components.

- Software as the machine’s backbone. We have a long track record in software engineering for mechatronics. We have the capacities to translate the customer’s requirements into smarter systems for advanced manufacturing facilities, with the help of software.

- Machine dynamics and performance over time. At NTS, we have built and developed a toolbox to simulate vibrational shapes and machine performance. To close the design loop, experimental methods are available to measure and validate these predictions.

- Electrical engineering for durable and long-lasting cabling. In moving systems, durable mechanical designs are accompanied by solid electrical designs that are equally capable to match the expected lifetimes of the system. NTS works with a wide set of solutions to cover most industrial applications.

“As your partner, NTS implements mechatronics system solutions consisting of custom made precision mechanics, off the shelf and (semi-)custom actuation, off the shelf sensors, and re-usable motion control hardware and software building blocks.”

Patrick Strating

Senior Technology Manager of NTS Hengelo

Industrialization – From Development to Series Production

At NTS, we take care of the entire mechatronic process from feasibility research to prototyping and industrialization. In the early stages of development, we involve our own factories to make sure a design is optimized for performance and production right after its release. With a multidisciplinary and customer-oriented team, we transform your requirements into a high-performing and state-of-the-art system. The result? Scalable solutions, short time-to-market, maximum quality and lowest overall cost. Together we realize the next generation of high-tech systems.

Download our Whitepaper ‘Scalable Positioning Systems for Minimal Time to Market and Low Cost’

In this whitepaper, we explain how the H-bridge design contributes to a reduction in NRE and time to market.