NTS Eindhoven

Cleanliness, cleanroom mechatronic assemblies, frames, sheet metal and precision parts

Being a one-stop-shop as a company brings tremendous benefits to our customers. But being a one-stop-shop as a site even more. Located in the heart of the Brainport region, surrounded by technological innovation and development, at NTS Eindhoven we do what we do best: unburden our customers and accelerate the future. With a gathering of our mechatronics, precision, and metal locations, combined with our focus on development & engineering, at NTS Eindhoven we make sure to answer the needs of the market.

Core Competences at NTS Eindhoven

Answering the needs of the market – that starts with a focus on what is necessary for high complex mechatronics assemblies and manufacturing of frames, sheet metal and precision parts. The most essential competence required for such modules and systems are vacuum and cleanliness. At NTS Eindhoven, contamination control is a core competence, and we lead with cleanliness, through the complete lifecycle. This approach contributes greatly to the success of developing and manufacturing complex modules. Next to cleanliness, we excel at (rapid) prototyping. This is because we are involved early on, in the product lifecycle, which means that we manage non-optimal products. The benefit of our great development & engineering presence is that we can create high-complexity prototypes, fast and repeatable.

An Optimized Supply Chain

Due to a good collaboration between (co-)development & engineering, our metal section and our precision section, manufacturability is guaranteed. Each discipline complements the other: at our metal section we do the protoyping, while at our precision section, we create complex high-precision parts with the most critical machines. In-house communication ensures optimal workflow. No matter the phase of the product lifecycle or the needs of the customer: The combination of our different disciplines at NTS Eindhoven makes us flexible and lets us work in a customized manner. And due to that, the focus on process remains efficient, we shorten time-to-market and repeatability is secured.

NTS Eindhoven is about Teamwork

Our positioning within the Brainport region, together with the fact that factories of different disciplines are present at NTS Eindhoven, are the main contributions to our success. How? Because we believe that a strong emphasis on ‘together’ gets the best out of your technological development. Short lines between different teams, but also suppliers and customers, are important there. That is why NTS Eindhoven has a team-oriented focus, which we proudly carry on to the rest of the world.

Download our Cleanliness Whitepaper ‘Looking ahead to our Customers’ future Cleanliness Requirements’

NTS has designated cleanliness as a core competence and has a holistic, systematic approach in place to continue anticipating and acting on developing market requirements. That, combined with our unique manufacturing knowledge and how to apply cleanliness to that area of expertise, is what makes NTS a strong partner for leading OEMs in demanding markets. In this whitepaper, our Cleanliness Competence Team discusses four subjects that are at the heart of cleanliness:

- Drivers of cleanliness in Semiconductor, Analytical & Life Sciences

- Cleanliness training, education and metrology

- Cleanliness and the manufacturing flow

- The future of cleanliness

NTS Whitepaper Cleanliness

NTS Eindhoven in Numbers

0

0

Precision Frames & Cabinets

In realizing high-precision frames and cabinets, we take manufacturability, cleanliness, and application look-and-feel into account. Our skilled workforce has all technical know-how and works hard to meet the challenges of our OEM customers and shorten their time-to-market.

Read more

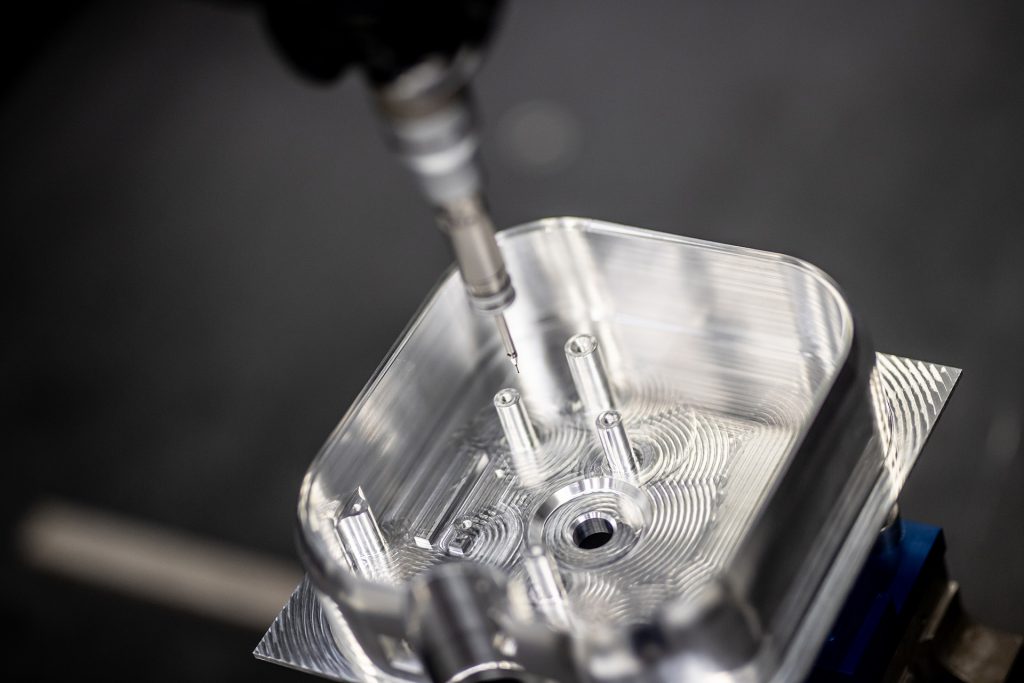

Precision Components

While components are getting smaller, we are getting more precise. NTS is one of the few in the world that can manufacture parts under an accuracy of (less than) one-thousandth of a millimeter. Having all expertise in-house makes us a one-stop-shop for precision components.

Read more

System Assembly

From Series Assembly and Cleanroom Assembly to Rapid Prototyping and New Product Introduction: we excel at putting all pieces together on time and ensuring the final product to meet the customer’s requirements.

Read more

Cleanliness & Vacuum

Cleanliness is a core competence at NTS. It is embedded in all layers of the organization. Every step of our development and manufacturing processes are designed with cleanliness optimization in mind. We invest heavily in equipment as well as knowledge-led expertise in contamination control and vacuum technology, to meet the strictest challenges

Read moreContact

Want to know more?

In case you would like to contact us, you can fill in the contact form here. We will respond to you as soon as possible.Locations

NTS CombiMetaal

Hurksestraat 7

5652 AH Eindhoven

The Netherlands

NTS Mechatronics

Dillenburgstraat 9

5652 AM Eindhoven

The Netherlands

+31 (0)40 259 72 00

NTS Precision

Hurksestraat 7a

5652 AH Eindhoven

The Netherlands